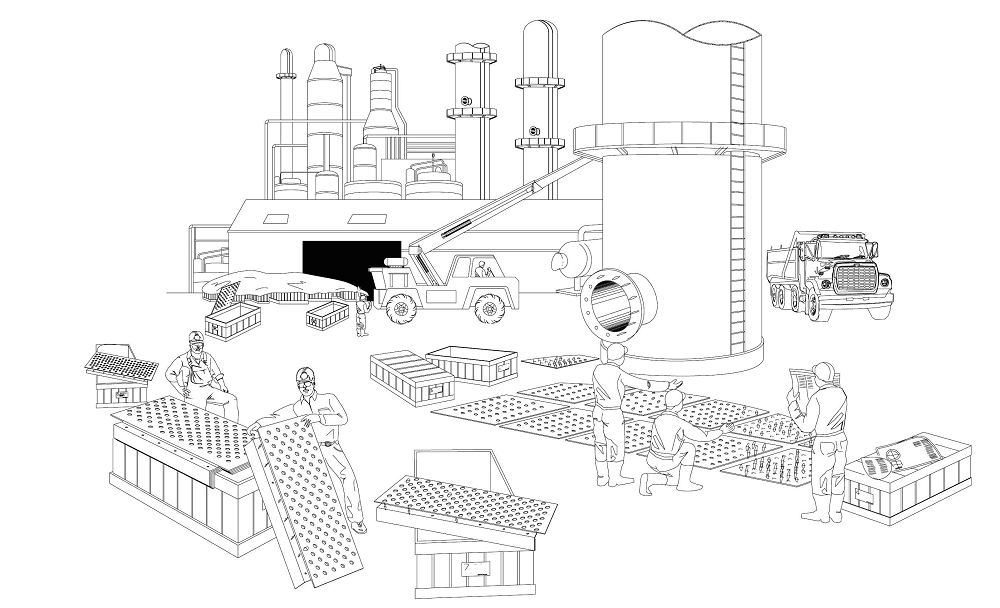

Distillation Trays — A Full Line of Trays

Trays at Saiptech are engineered using proprietary in-house programs that generate comprehensive hydraulic output for each specific application. The final design is optimized for both cost efficiency and operational performance. Our seasoned design engineers can specify the optimal valve type — from venture cage valves for minimal pressure drop to mini fixed valves for maximum process efficiency.

Supply of New Trays for Newly Constructed Columns

Saiptech boasts extensive expertise in supplying fully hydraulically designed trays for brand-new columns. We prioritize the layout and design of vapour and liquid inlets to ensure peak operational performance.

Internal configurations are meticulously engineered to fully comply with technical specifications while ensuring ease of installation. Specialized tray designs can also be tailored to reduce on-site installation timeframes.

Replacement of Existing Trays on a Like-for-Like Basis

Saiptech provides partial or full replacement of existing distillation trays, typically for routine maintenance projects. Our trays are precision-engineered to fit existing support structures and deliver identical operational performance to the original equipment.

We supply valves with equivalent performance and identical downcomer sizing to ensure consistent column operation. Our commitment extends to emergency scenarios: in the event of unplanned equipment failure, replacement trays can be rapidly designed and manufactured to minimize downtime.

Our experienced drafters specialize in translating theoretical designs into detailed 3D models, eliminating potential installation conflicts and ensuring seamless on-site integration.

Upgrading Existing Columns for New Operating Conditions

Older columns often require upgrades to accommodate new flow conditions. We have developed modular systems that allow for modifications to downcomer sizes and overall tray dimensions — eliminating the need for hot work or welded modifications to existing vessel attachments. High-capacity tray designs can also enhance column performance without the cost of full column replacement.

With over a decade of experience in designing and manufacturing fractionation trays and column internals, Saiptech’s engineering team combines proprietary R&D with deep process industry expertise. This enables us to replace trays from nearly all original equipment manufacturers (OEMs) with precision and reliability.

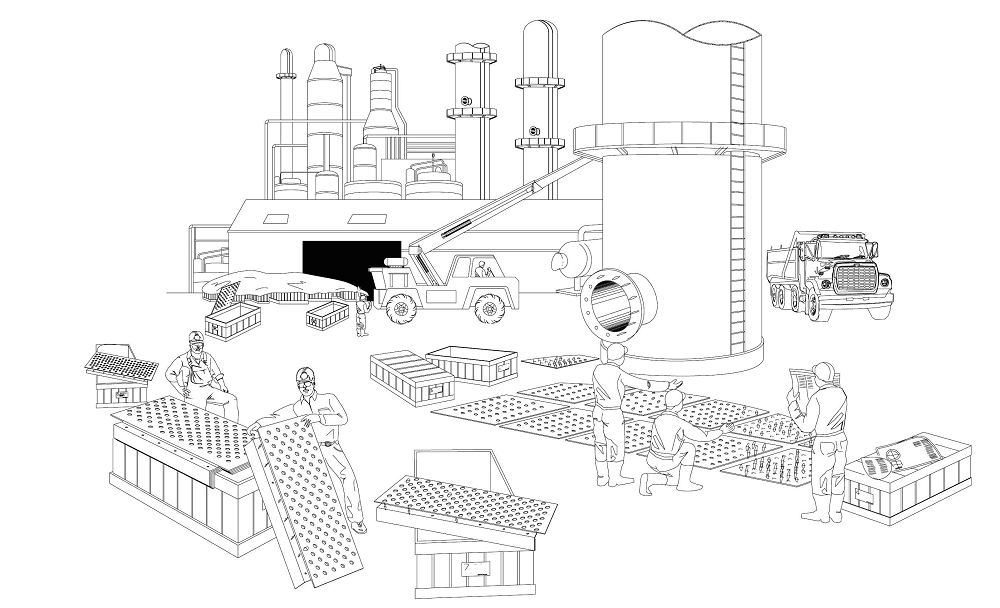

The available trays range from conventional to high-performance designs, including the latest technological advancements:

-

Round and Caged Floating Valve Tray

-

Fixed Valve Tray

-

Sieve Tray

-

Bubble Cap Tray

-

Tunnel Tray/Thormann Tray

-

Cartridge Tray

-

Dual Flow Tray

-

Disk & Donut Tray

-

Other Custom Trays