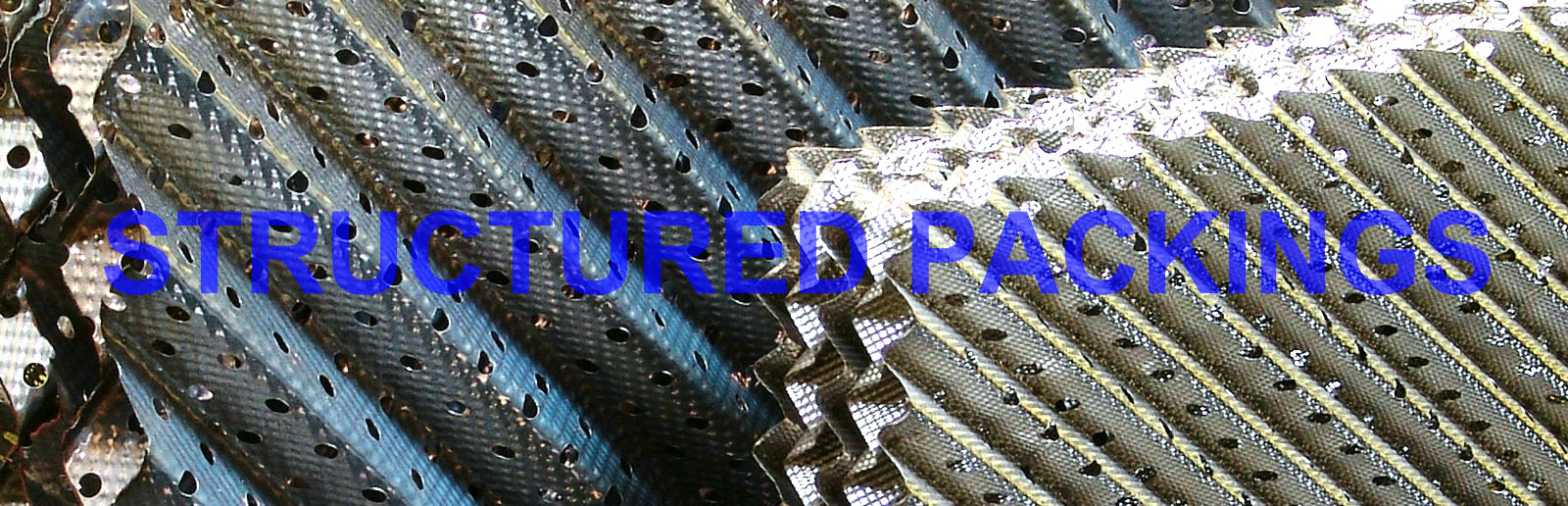

The selection of the optimal structured packing for a specific separation process is the most critical decision in packed column design. With a diverse portfolio of packing configurations available, engineering experience and data-driven analysis are essential to balance three core parameters: separation efficiency, operational capacity, and capital cost. This delicate tradeoff defines the performance and economic viability of distillation, absorption, and liquid-liquid extraction systems.

A fundamental design tradeoff governs structured packing performance: higher surface area typically enhances mass transfer efficiency but may reduce open area and increase pressure drop—directly impacting column diameter and energy consumption. Saiptech's proprietary structured packing range resolves this conflict through optimized corrugation geometry and material engineering, maximizing both effective surface area (for mass transfer) and open area (for vapor-liquid flow). The result is industry-leading separation efficiency, low pressure drop, and exceptional mechanical strength for extended service life in harsh operating environments.

Structured packings are distinguished by their high-performance, flexible application scope, and adaptability to complex fractionation challenges. Key advantages include superior separation efficiency, excellent liquid wettability (even at low liquid loads), minimal pressure drop, and scalability from pilot to commercial-scale columns. These attributes make them the preferred choice for critical applications across distillation (crude oil fractionation, solvent recovery), absorption (acid gas removal, CO? capture), and liquid-liquid extraction (petrochemical refining, specialty chemical production).Manufactured to strict industry standards (API, ASME, DIN), Saiptech structured packings are fully customizable to fit existing column internals—including retrofits requiring installation between legacy weld-in attachments. Leveraging decades of pilot-scale test data and in-house design software, our engineering team delivers optimal packing selection tailored to process conditions (temperature, pressure, corrosivity, fluid properties). Combined with our expertise in complementary column internals (liquid distributors, collectors, hold-down plates), we offer a one-stop solution for fully optimized packed column design and performance.