Distillation Trays

Valve Tray

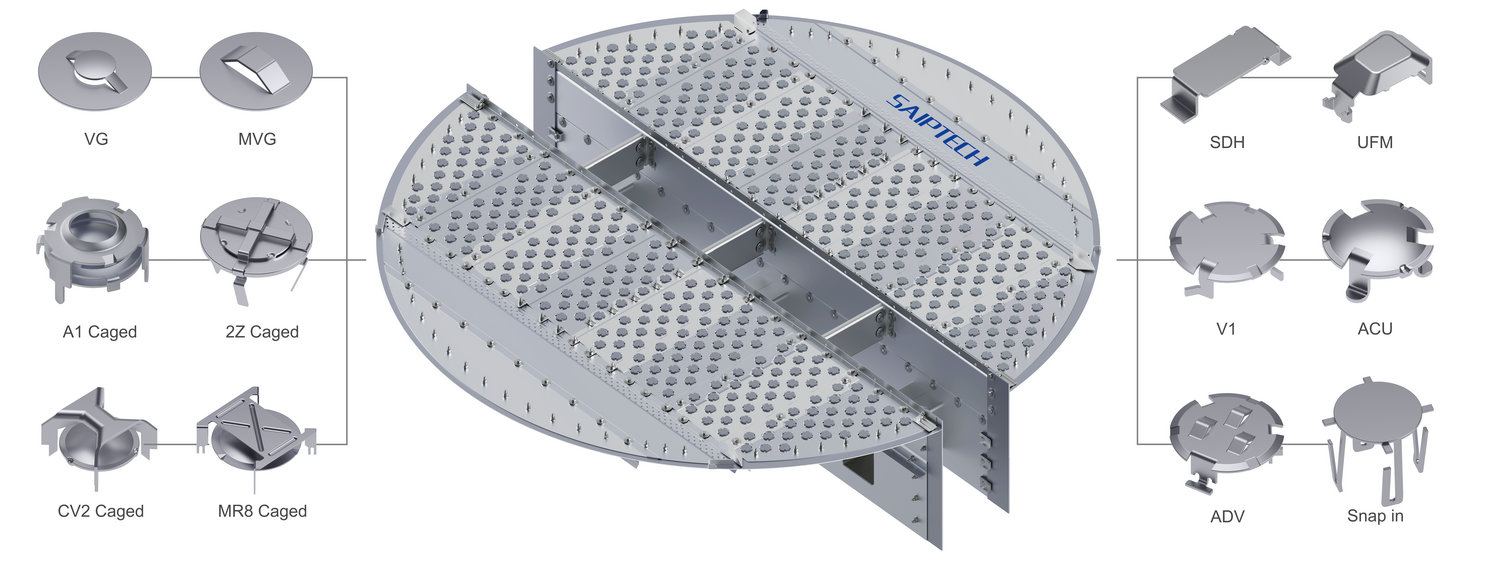

Versatile Tray Valves---We have valves for all your new construction, maintenance & replacement requirement

With our technical expertise in design, manufacturing, and installation, a well designed valve tray generally provides the most economically attractive solution for grassroots column construction projects. Valve trays combine high capacity and excellent efficiency with a wide operating range. Using proprietary design techniques and wide range of valve types available for valve trays, design engineers at Saiptech can assist you in optimizing performance for your application.

Common Types

- Float Valves---Round & Rectangle

- Fixed Valves

- Caged Valves

- Mini Type

- Snap In